Creating Sustainable Supply Chain

SUPPLY CHAIN MANAGEMENT ACTIVITIES

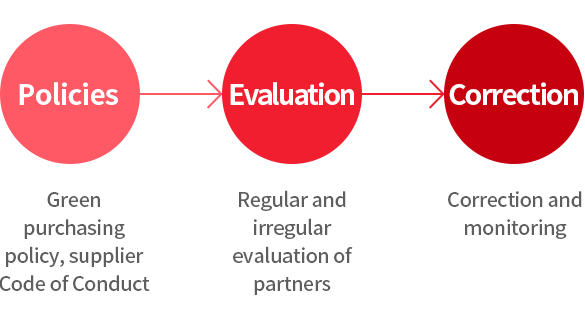

Kumho Tire complies with all laws and regulations as well as protecting its employees and stakeholders through a code of conduct based on labor rights, human rights, safety and health, environment, and ethical awareness.

Also, we promote eco-friendliness by being aware of the green purchasing guidelines in the entire process encompassing supply, transportation, and unloading.

We also prefer using products receiving green purchase certification for our consumable materials. We are also expanding green purchase as well as various activities such as discovering and introducing eco-friendly materials.

- Policies : Green purchasing policy, supplier Code of Conduct

- Evaluation : Regular and irregular evaluation of partners

- Correction : Correction and monitoring

SUPPLY CHAIN ESG MANAGEMENT SyStem

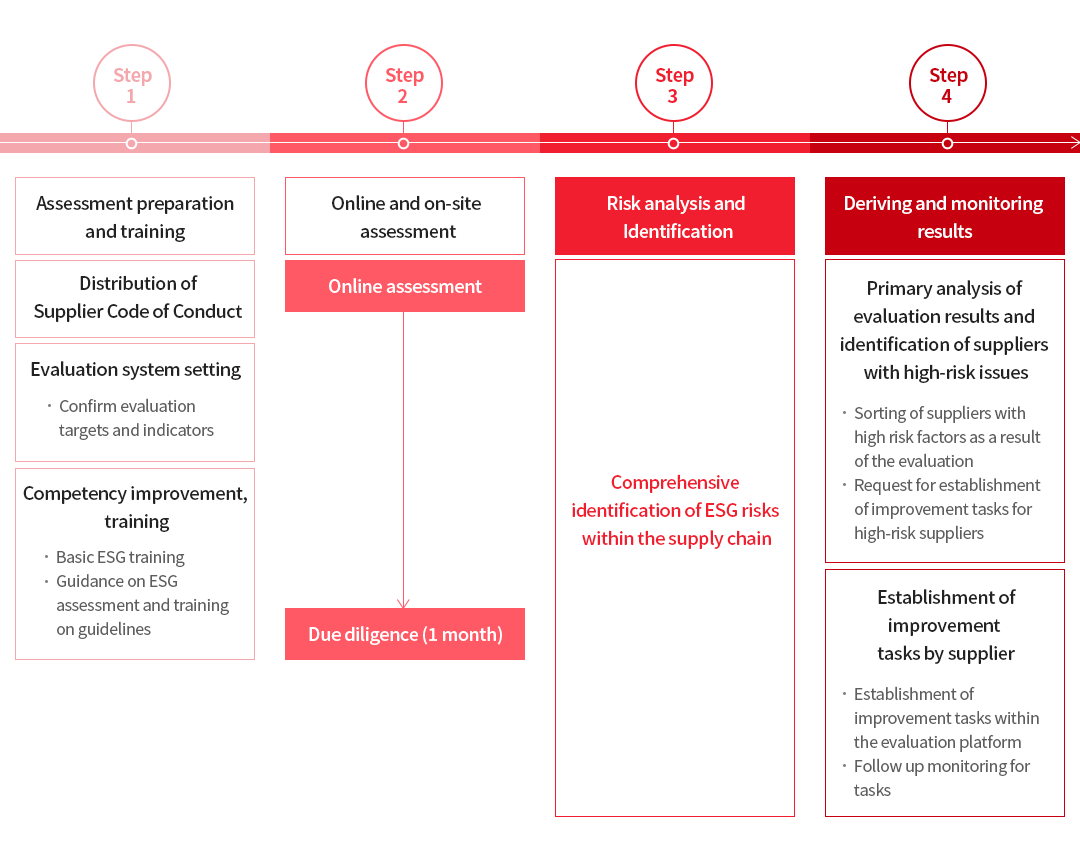

Kumho Tire presents the Supplier Code of Conduct as a guideline for integrating ESG in the supply chain management. Also Kumho Tire has established and is operating a supply chain ESG assessment process in order to identify and systematically manage ESG risks within the supply chain.

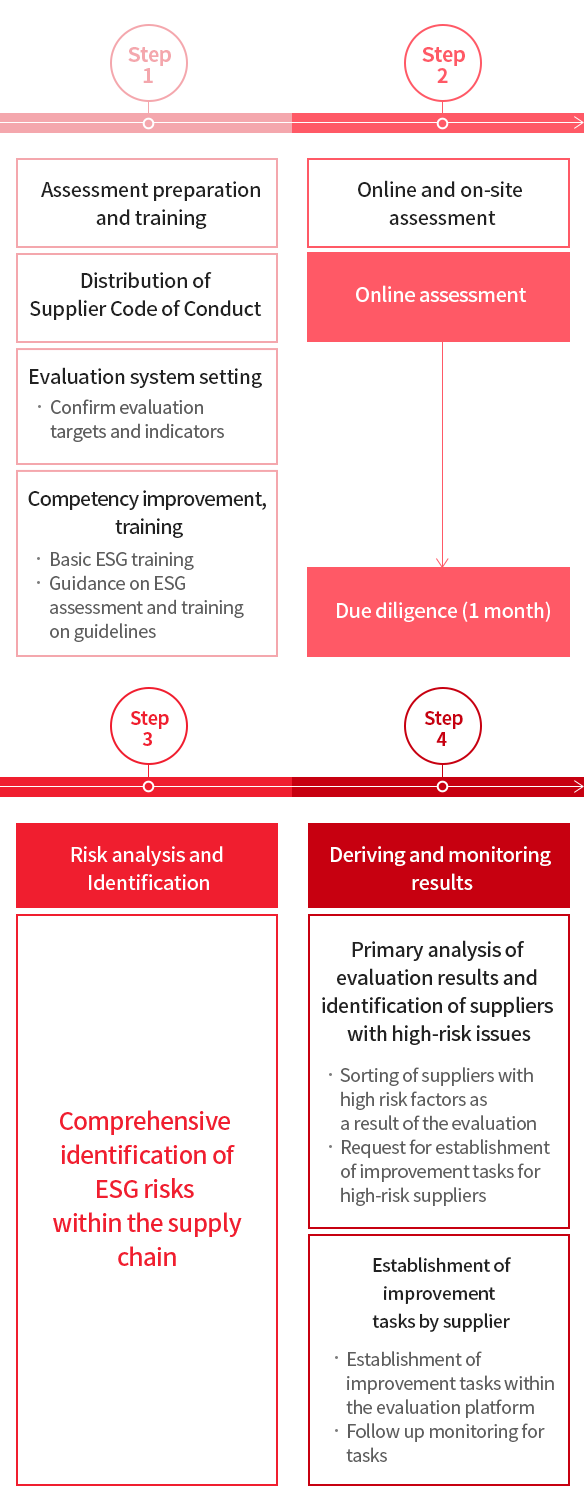

- Step1 :

- Assessment preparation and training

- Distribution of Supplier Code of Conduct

- Evaluation system setting (Confirm evaluation targets and indicators)

- Competency improvement, training (Basic ESG training , Guidance on ESG assessment and training on guidelines)

- Step2 :

- Online and on-site assessment

- Online assessment

- Due diligence (1 month)

- Step3 :

- Risk analysis and Identification

- Comprehensive identification of ESG risks within the supply chain

- Step4 :

- Deriving and monitoring results

- Primary analysis of evaluation results and identification of suppliers with high-risk issues (Sorting of suppliers with high risk factors as a result of the evaluation Request for establishment of improvement tasks for high-risk suppliers)

- Establishment of improvement tasks by supplier (Establishment of improvement tasks within the evaluation platform Follow up monitoring for tasks)

-

Environment

- Environmental risk

- Environmental management system

- Greenhouse gas, water and wastewater, waste, air quality, etc.

-

Human rights and labor

- Human rights and labor risk

- Safety and health risk

- Human rights/labor standards and practices

- Workplace safety

- Supply chain human rights and labor, etc.

-

Ethics and governance

- Ethical risk

- Ethical management

- ESG management and information disclosure

- Governance, etc.

-

Product and service responsibility

- Risks by country or region

- Product and service risk, etc.

SUPPLY CHAIN ESG MANAGEMENT SyStem

Kumho Tire presents the Supplier Code of Conduct as a guideline for integrating ESG in the supply chain management. Also Kumho Tire has established and is operating a supply chain ESG assessment process in order to identify and systematically manage ESG risks within the supply chain.

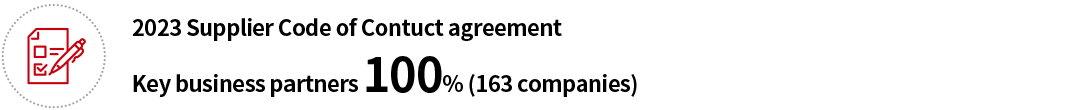

- 2022 Target for partners Signing the code of conduct : 100% of key business partners (51 companies)

- Partner Company Regular Evaluation Completion Rate : 61% (32 companies)

(Subject selection criteria : companies with transaction of 2 billion won in the previous year, companies evaluated poorly in the previo us year, etc.)

GLOBAL PLATFORM FOR SUSTAINABLE NATURAL RUBBER

NATURAL RUBBER POLICY

Kumho Tire has been a founding member of the ‘Global Platform for Sustainable Natural Rubber (GPSNR) since 2018. To enhance the sustainability of natural rubber, we established a policy on natural rubber by reflecting the GPSNR standards and disclosed the policy on our website

Responsible management of conflict minerals

*Conflict minerals include Tin, Tantalum, Tungsten, and Gold, which are unethically mined in conflict regions including ten African countries such as the Democratic Republic of the Congo, Sudan, Congo, and Angola, and which benefit armed groups directyly or indirectly in those countries.

korea

korea

china

china

japan

japan

vietnam

vietnam

australia

australia

thailand

thailand

germany

germany

uk

uk

spain

spain

austria

austria

russia

russia

poland

poland

france

france

italy

italy

usa

usa

canada(eng)

canada(eng)

brazil

brazil

egypt

egypt